UPDATED 1 Sept: The EI library in London is temporarily closed to the public, as a precautionary measure in light of the ongoing COVID-19 situation. The Knowledge Service will still be answering email queries via email , or via live chats during working hours (09:15-17:00 GMT). Our e-library is always open for members here: eLibrary , for full-text access to over 200 e-books and millions of articles. Thank you for your patience.

New Energy World™

New Energy World™ embraces the whole energy industry as it connects and converges to address the decarbonisation challenge. It covers progress being made across the industry, from the dynamics under way to reduce emissions in oil and gas, through improvements to the efficiency of energy conversion and use, to cutting-edge initiatives in renewable and low-carbon technologies.

Could hydrogen combustion engines power more vehicles – rather than fuel cells?

12/6/2024

8 min read

Feature

A lot of effort is going into hydrogen-fuelled transport solutions. These are usually fuel cells generating electricity to power electric motors. But some manufacturers see hydrogen as an alternative fuel for internal combustion engines to power vehicles directly, reports Toby Clark.

On the face of it, combusting hydrogen seems an odd proposition: the overall efficiency of a fuel cell system is better, which is one reason why mainstream car manufacturers are concentrating on fuel cells (FC) and battery-electric (BEV) solutions. BMW built a series of hydrogen-fuelled luxury cars, but ultimately gave up on the technology. But for some applications, an internal combustion engine (ICE) is more attractive than either.

Construction equipment

Tim Burnhope, JCB Group Director of Special Projects, reckons hydrogen engines are an easy swap: ‘If you were to jump off a diesel backhoe and on to a hydrogen one, you would notice no difference in terms of power, torque, performance.’

But the journey was painstaking. ‘We had the world’s first electric mini-excavator, [and] we’ve sold over 20,000 machines.’ On urban sites, charging is easy, but larger vehicles often operate far from mains electricity, and diesel generators would defeat the decarbonisation object. JCB concluded that batteries were impractical on larger machines: ‘For a 20-tonne excavator to run for 16 hours, we’d need 1,000 kWh – 10 tonnes and £400,000 of batteries – and at least a megawatt charger. Our customers said: ‘If we use a machine 24 hours a day, we don't have time to charge it; we just want to put fuel in.’

‘So we started to look at different fuels – HVO (hydrogenated vegetable oil), biogas, biodiesel, e-fuels, ammonia – and hydrogen had all the green ticks. We thought the only technology available would be a fuel cell, so we got a couple of excavator prototypes running.’ But to run efficiently, a fuel cell needs near-constant load: ‘Where you need to go from zero to full power it’s a challenge. You need to manage those fluctuations with batteries, which are expensive.’

Other reservations such as the need for cooling led JCB to abandon the technology. Burnhope continues: ‘So we’ve gone into hydrogen engines, and the beauty is you’ve got the same supply chain.’ JCB’s four-cylinder, 4.8-litre indirect-injection turbocharged spark-ignition unit puts out a modest 55 kW – ‘about 65% of our product range is powered by that’, he says. It runs lean, for efficiency – ‘1% more efficient than a diesel’ and cool, to minimise NOx (nitrogen oxides) emissions.

JCB’s portable refuelling module, mounted on a truck or tractor, carries 100 kg of gas at 500 bar. Now rental companies can do a ‘milk run’ and refuel on site. ‘What the customers really like is the machines can be serviced and repaired on site just like today’s machines.’

‘If you were to jump off a diesel backhoe and on to a hydrogen one, you would notice no difference in terms of power, torque, performance.’ – Tim Burnhope, JCB Group Director of Special Projects

JCB sees India as a huge market, as does Cummins – the US firm is building a plant with Tata to make hydrogen engines, and is developing versions of its 6.7- and 15-litre truck engines.

Meanwhile, Hyundai Doosan has shown an 11-litre engine putting out 300 kW (402 hp). It meets upcoming Euro 7 emissions regulations and is designed for heavy trucks and construction equipment, with production starting in 2025.

Truck and rail initiatives

The US Hydrogen Opposed-Piston Working Group is testing an opposed-piston two-stroke (OP2S) hydrogen engine for highway trucks. The 10.6-litre, six-piston engine (with three cylinders and two crankshafts) is being developed by Achates Power. Its ‘no cylinder head’ design is said to suit the characteristics of hydrogen.

Almost all applications for hydrogen in rail vehicles have used fuel cells, but Iarnród Éireann (Irish Rail) is to trial a converted 071 Class diesel locomotive with a hydrogen retrofit from Latvian firm DIGAS. Static testing takes place this year, with service trials in 2025. Jim Meade, CEO of Iarnród Éireann, says the firm has 12 such diesel locomotives in freight operations: ‘If the tests are successful, these locomotives can be converted to greener and more efficient alternatives.’

On the road

As far as road cars are concerned, there are rumours that Mazda is working on a hydrogen-powered Wankel rotary engine, perhaps as a BEV range-extender. The Wankel engine runs with minimal vibration and would benefit from the rapid flame speed of hydrogen.

Meanwhile, Ferrari surprised many in February with a patent for a hydrogen road car engine. Unusually, the straight-six unit is inverted, with cylinder heads at the bottom and dry-sump lubrication. This seems to be a way to accommodate a complex electrically-assisted turbocharging setup – presumably to improve throttle response – as well as the tanks required for gaseous or liquid hydrogen.

Racing

A very different, but no less appropriate, application is motor racing. Despite high-profile battery-electric race series such as Formula E, many are reluctant to give up the light weight and noise of internal combustion engines.

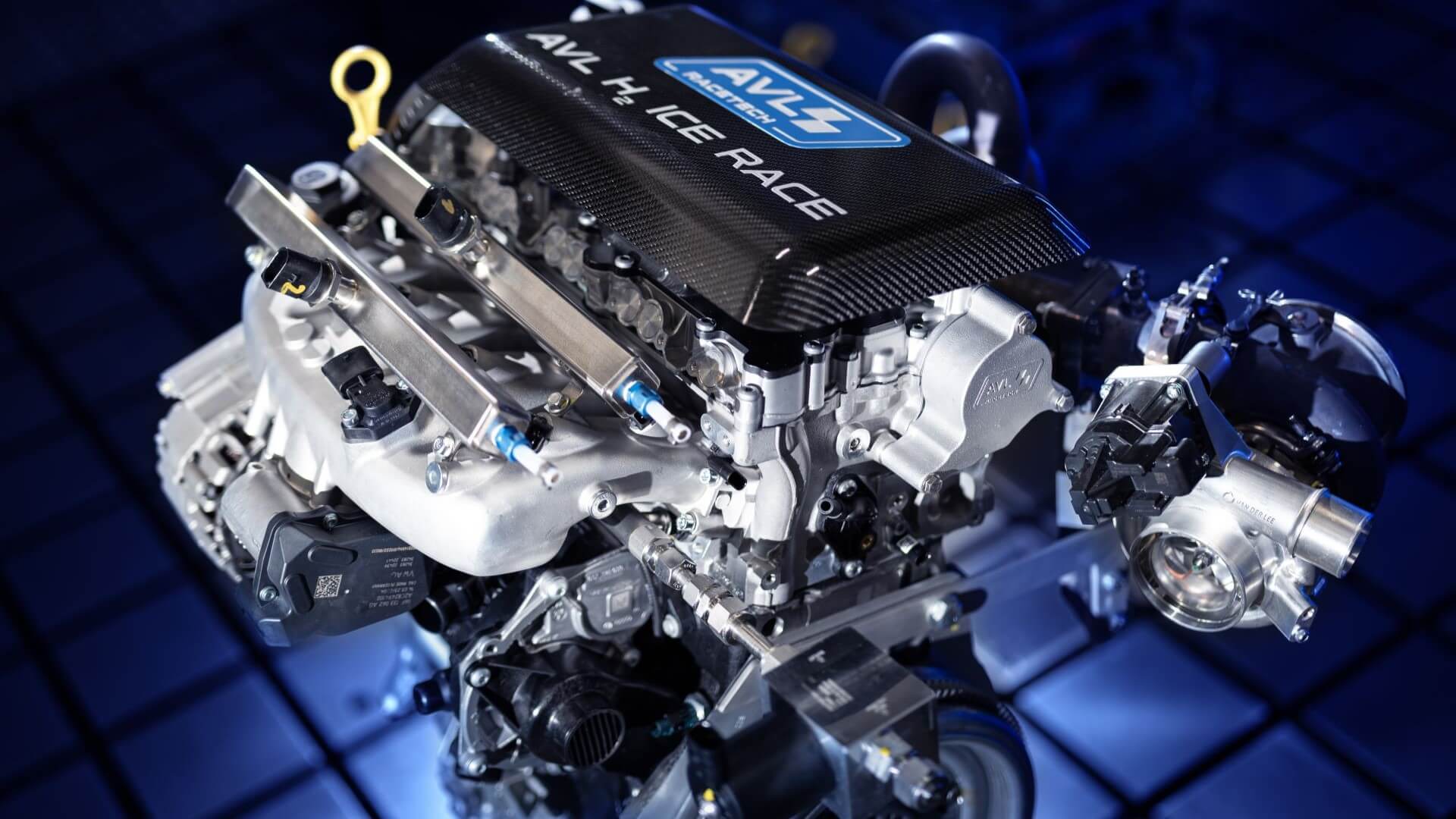

While Porsche pursues synthetic liquid fuels for new and classic engines, several other firms are examining hydrogen. Like construction equipment, racing engines need good transient response, to be robust and to give peak power for sustained periods. However, some of the numbers are very different: whereas JCB’s engine has a specific power output of around 12 kW/l, AVL Racetech is testing an engine with 150 kW/l. The turbocharged, water-injected 2-litre prototype puts out 302 kW (410 hp) at 6,500 rpm – with a peak torque of 505 Nm at 4,000 rpm.

AVL Racetech is testing an engine with 150 kW/l – the turbocharged, water-injected 2-litre prototype puts out 302 kW (410 hp) at 6,500 rpm

Photo: AVL Racetech

The Le Mans 24-hour race will include FC and ICE hydrogen cars from 2026. Bosch and Ligier demonstrated the 420 kW, 3-litre JS2 RH2 car at last year’s event.

Toyota also unveiled its GR H2 racing concept at Le Mans last year. The firm previously entered a hydrogen Corolla into the 2021 Fuji 24-hour race. This three-cylinder, 1.6-litre turbocharged car completed over 1,600 km, but the team spent four hours refuelling – in 35 seven-minute sessions – and eight hours on maintenance and inspection. Since then, Toyota has competed each year – in 2023 with liquid hydrogen fuel – and has demonstrated a hydrogen version of its GR Yaris rally car.

Toyota is also associated with HySE (Hydrogen Small mobility and Engine technology), a Japanese research group developing hydrogen-powered engines for ‘small mobility’ applications. The group’s HySE-X1 buggy successfully completed this year’s Dakar Rally, powered by a supercharged 1-litre motorcycle engine.

The simplest fuel of all?

Hydrogen seems like a perfect fuel: without carbon, it can’t produce CO2 or sooty particulates. Burning hydrogen in oxygen produces only heat and water vapour. But only 21% of our atmosphere is oxygen – 78% is nitrogen, and at high temperatures this reacts to create nitrogen oxides (NOx). These are bad for air quality and promote damage to the ozone layer. And in practice, a tiny amount of CO2 is produced as some lubricating oil gets past the piston rings and is burned in the combustion chamber.

Hydrogen is not a straight alternative to fossil liquid or gaseous fuels. It can be burned over a wide range of mass air/fuel ratios (λ or lambda), so you can tailor the mixture for different characteristics. The stoichiometric (‘ideal’) ratio is where λ=1. Running ‘lean’ – with more air – improves the overall thermal efficiency. Although a petrol engine can’t go much leaner than λ=2, a hydrogen engine can operate at λ=5 or more.

Racing applications need more power, so they run richer (lower λ). Hydrogen’s flame speed is high, so higher operating speeds are possible. And the quenching distance is smaller, using more of the combustion chamber. Hydrogen resists uncontrolled ignition due to compression (‘knock’), so it can be used at higher compression ratios, again improving efficiency. But easy ‘pre-ignition’ means combustion can occur in the intake, so racing engines use water injection to cool the mixture.

NOx emissions can be removed with a diesel-style catalytic converter, or exhaust gas recirculation (EGR) and other techniques to reduce combustion temperature. But the most significant way to eliminate NOx is to run lean (λ>2).

JCB uses indirect (port) fuel injection, but some manufacturers favour direct-injection (DI) systems at high pressures (150–300 bar) to overcome pre-ignition – and to inject more hydrogen, raising power outputs.

Liquid hydrogen fuelling allows cryogenic port injection (CPI), where low-temperature hydrogen cools the inlet air, improving thermal efficiency – the European Union’s HYICE project reportedly achieved 44%.

Energy density

The energy density of a fuel can be measured in terms of energy (in Megajoules) per unit of mass (MJ/kg) or per unit of volume (MJ/l).

Hydrogen’s energy density by mass is about 120 MJ/kg, compared with 44 MJ/kg for petrol. But hydrogen gas is so light (84 g/m3 at atmospheric pressure, compared with 1,203 g/m3 for air and 700,000 g/m3 for liquid petrol) that for a given volume its energy density is very low.

Most hydrogen-powered vehicles store the gas under high pressure (often 700 bar) in tanks of carbon fibre composites. But even at this pressure, one litre of hydrogen weighs just 40 grammes – providing the same energy content (4.8 MJ) as 109 grammes of petrol. A litre (700 grammes) of petrol provides 31 MJ of energy – or over six times that provided by hydrogen.

Liquid hydrogen looks promising as you can store around 75% more hydrogen as a liquid at atmospheric pressure than as a gas at 700 bar. But it must be kept at –253°C; and even with a vacuum-insulated tank, ambient heat warms the fuel. This turns it into gas, which needs to be bled off to keep the pressure down; BMW’s Hydrogen 7 would bleed off all its fuel in a fortnight.

In trucks or other vehicles which are refuelled daily, liquid hydrogen is more feasible. But its volumetric energy density is still much lower than petrol or diesel: one litre weighs around 71 grammes, giving you 8.5 MJ – barely a quarter of the energy of the same volume of petrol or diesel.

- Further reading: ‘Largest US liquid green hydrogen plant commissioned’. Plug Power has started production of liquid green hydrogen at its vertically integrated plant in Georgia, claimed to be the largest electrolytic liquid hydrogen production plant and largest PEM (proton exchange membrane) electrolyser deployment currently operating in the US.

- Find more about Air Liquide and Siemens Energy’s joint venture gigawatt electrolyser factory in Berlin, Germany, which aims to manufacture low-carbon hydrogen at industrial scale and competitive cost.