UPDATED 1 Sept: The EI library in London is temporarily closed to the public, as a precautionary measure in light of the ongoing COVID-19 situation. The Knowledge Service will still be answering email queries via email , or via live chats during working hours (09:15-17:00 GMT). Our e-library is always open for members here: eLibrary , for full-text access to over 200 e-books and millions of articles. Thank you for your patience.

New Energy World™

New Energy World™ embraces the whole energy industry as it connects and converges to address the decarbonisation challenge. It covers progress being made across the industry, from the dynamics under way to reduce emissions in oil and gas, through improvements to the efficiency of energy conversion and use, to cutting-edge initiatives in renewable and low-carbon technologies.

Hydrogen compression: the missing link in the hydrogen value chain

2/10/2024

8 min read

Feature

The main technology involved in joining the production side to the consumption side in the hydrogen value chain is a gas compressor. These are examined in the Energy Institute’s new research report: Gas Compressors for 100% Hydrogen. The new report identifies six typical major applications, ranging up to very large flowrate compressors for gas pipelines and geological storage, where the biggest unknowns exist currently, writes Ian Arbon CEng CEnv FEI, Senior Partner of Engineered Solutions, a sustainable engineering and management consultancy.

In a bid to fulfil international ambitions to combat climate change by reducing greenhouse gas (GHG) emissions, there has been a proliferation of hydrogen projects in what has become known as the ‘hydrogen value chain’ (H2VC) in the past few years. These are often localised projects with little by way of national or international co-ordination, which has led to most of these projects being located in either the production or the consumption sectors of the H2VC.

Whilst there are many worthwhile projects in both of these sectors, little thought appears to have been given to how the two sectors can be joined together. For example, how does ‘green’ hydrogen produced in relatively small quantities from electrolysers at low pressures actually reach its market of, say, a high-pressure refuelling station located on the other side of the country?

Or, how does ‘blue’ hydrogen, produced in larger quantities, from steam methane reformers (SMRs) or autothermal reformers (ATRs) – reach its much greater markets in the process industries, cement making or steel making?

The answer to both questions, to a great extent, is hydrogen compression systems. It is perhaps surprising that so little attention has been given, so far, to this crucial link in the chain. This is set to change with the Energy Institute’s (EI) forthcoming research report: Gas Compressors for 100% Hydrogen.

A former (2022) EI publication, The Energy Balance Report, covered the H2VC from production, through transmission and storage, to consumption. It clearly demonstrated that while much work is being done on different aspects of production and consumption, very little research exists on transmission and storage. The main technology involved in joining the production side to the consumption side in the H2VC is a gas compressor of some type. Gas compressors are the primary technology for these functions. The report demonstrated that hydrogen compressors are radically different in physical size, power consumption and cost, from those designed for natural gas.

Hydrogen compression: It is perhaps surprising that so little attention has been given, so far, to this crucial link in the chain.

How do compressors support the hydrogen value chain?

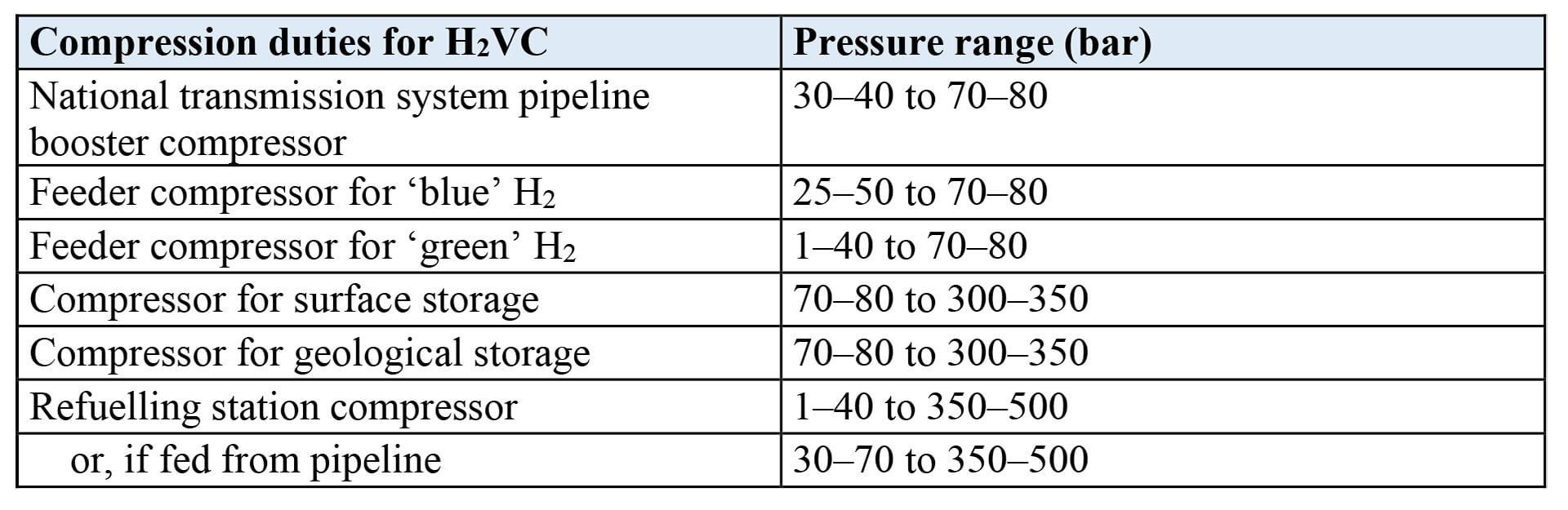

The new EI report attempts to cover all the main compression applications in the H2VC and identifies six major typical applications. They range from low flowrate compressors working with the output of electrolysers or reformers, to compressors for very high pressures (for example, for vehicle refuelling) and then on to very large flowrate compressors for gas pipelines and geological storage, see Table 1. Since the biggest ‘unknowns’ at the present time are at the large flowrate end of the spectrum, much of the report focuses on gas pipeline compressors.

Table 1: Typical main compression applications in the hydrogen value chain (H2VC)

Table 1: Typical main compression applications in the hydrogen value chain (H2VC)

Source: Gas Compressors for 100% Hydrogen report, Energy Institute, 2024

In contrast to these findings, other reports purporting to cover hydrogen compressor duties, particularly for gas pipelines, almost always ignore the different physical characteristics of hydrogen, or gloss over the issue entirely.

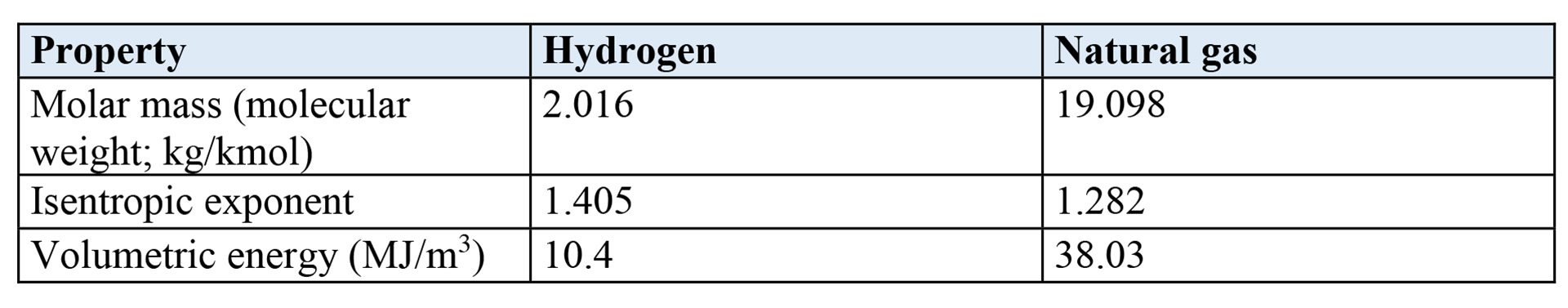

The main differences in physical properties between hydrogen and natural gas are as follows (taken from Table 5 of the EI’s hydrogen compression report) in Table 2.

Table 2: Main physical differences between hydrogen and natural gas

Source: Data taken from Table 5, Gas Compressors for 100% Hydrogen report, Energy Institute, 2024

There are other differences, but these are the most significant ones for compressor design. From volumetric energy, it can be seen that for existing infrastructure, only about one quarter of the energy can be delivered for the same volumetric flow. Conversely, using existing natural gas infrastructure with 100% hydrogen is likely to transmit only one quarter of the energy flow. Despite frequently made statements to the contrary, these facts are entirely dependent on the laws of physics, so ignoring them is potentially catastrophic for any project.

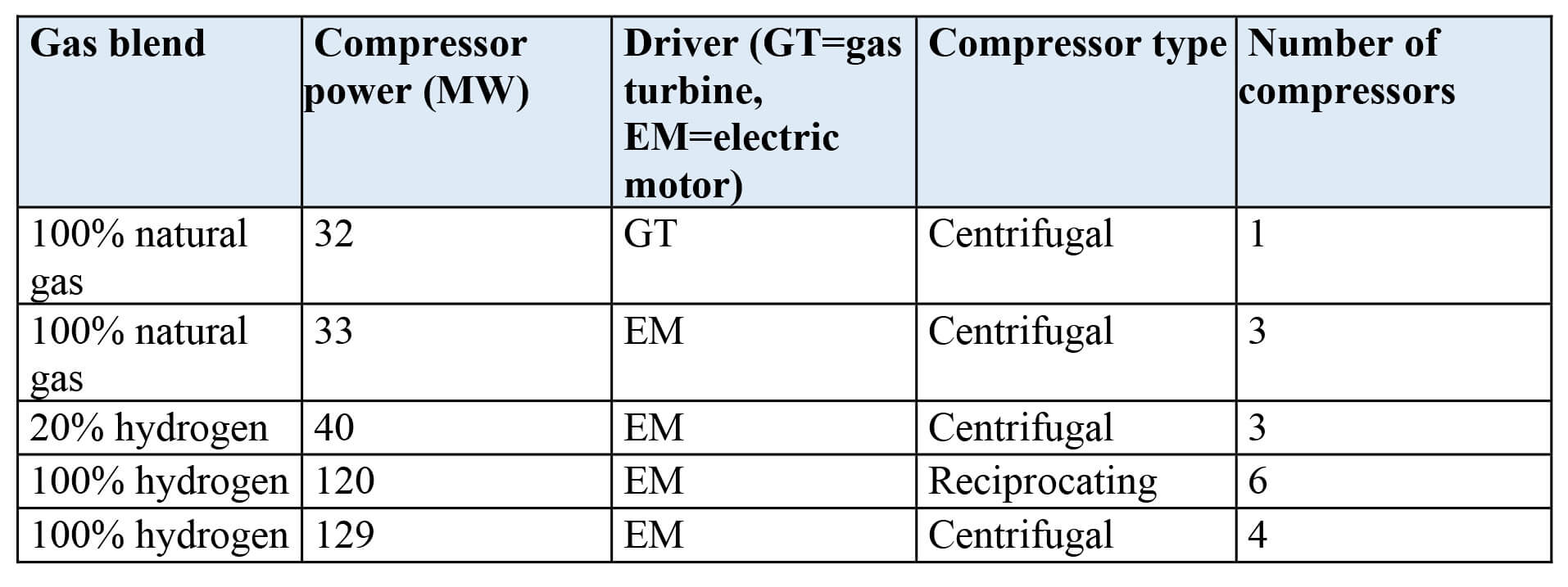

As an example of the difference that various gas blends can make, see Table 3, based on transmitting the same energy flow of gas through an existing gas pipeline. The data, taken from Table 3 of the EI’s hydrogen compression report, is based on actual compressor selections made by various reputable compressor OEMs for gas turbines (GT) and electric motors (EM).

Table 3: Various compressor set-ups to pass an equivalent energy flow across natural gas and hydrogen

Source: Data taken from Table 3, Gas Compressors for 100% Hydrogen report, Energy Institute, 2024

The new EI hydrogen compression report describes in some detail all of the different types of gas compressor which are used, or are intended to be used, for 100% hydrogen compression. These include positive displacement compressors (whether reciprocating, diaphragm, hydraulic, liquid piston or rotary screw); centrifugal dynamic compressors; and non-mechanical compressors, including metal hydrides, electrochemical and adsorption/desorption types. (Note that other types of compressor, not mentioned here, are unlikely to be used on hydrogen for a variety of reasons.)

The most challenging 100% hydrogen applications feature the horizontally-opposed reciprocating compressor for larger flowrates, and the diaphragm compressor for lower flowrates. Hydraulic and liquid piston types are increasingly used for low flowrate, high pressure applications. Rotary screw compressors can handle relatively high flowrates but are currently restricted to lower discharge pressures, so are primarily used as low pressure, first-stage ‘boosters’.

Non-mechanical compressors are being developed for hydrogen applications and are intended to avoid the many issues (reliability, maintenance intervals, noise, etc) associated with conventional mechanical types. However, it will be some time before these are commercially available due to the need for extensive and rigorous performance and endurance testing, as well as the need for a convincing safety case for hydrogen applications.

The oil and gas sector, and process industries, particularly in the UK, have a strong preference for centrifugal-type dynamic compressors for higher gas flowrates, usually because of higher reliability, availability and maintenance intervals than reciprocating compressors. This makes the sector reluctant to revert to using what they regard as older types.

However, while there are good examples with so-called ‘hydrogen-rich’ gases, the fact remains that very few examples exist of centrifugal compressors operating on 100% hydrogen. This is due to the huge disparity in physical properties, mentioned above, between hydrogen and most other process gases, including natural gas.

Whereas the other compressor types operate on the principle of positive displacement, that is, the compression space is gradually reduced in size to physically compress the gas, dynamic compressors operate on the principle of accelerating and decelerating molecules of the gas in thermodynamic stages. This becomes more difficult the lower the molecular mass of the gas, as hydrogen is the lightest element in the Periodic Table.

Each centrifugal compressor, therefore, will require many more impellers, running at much faster circumferential velocities (tip speeds) than is normally permissible for process gas compressors. The very conservative nature of the process industries – as exemplified by the American Petroleum Industry (API) standards for different compressor types, which are observed in most countries of the world – makes it likely to be some years before sufficient performance and endurance testing is satisfactorily completed to allow dynamic compressors to become commercially available for the hydrogen economy.

The UK’s natural gas pipelines are a vital energy vector for the country. The EI’s Energy Balance Report (see Tables 5.6 and 5.7 of the report) clearly demonstrates that any ‘re-purposing’ of existing natural gas pipelines to transmit 100% hydrogen, assuming the same energy flow of gas, would have severe consequences for the compression equipment.

The verification of these figures in the new EI Gas Compressors for 100% Hydrogen report suggests that in a repurposed pipeline, each compressor booster station would require three to four times the compression power, with four to six compressor units required (depending on type) to replace an existing single unit. There would also need to be compressor booster stations at more frequent intervals. Both physical footprint and capital cost would likely be an order of magnitude greater than for the existing natural gas stations.

The concept of repurposing existing natural gas pipelines is a good one and, in many ways, meets modern sustainability criteria (for example, UN Sustainable Development Goals) better than building a brand-new gas pipeline. See the article on Repurposing infrastructure for the energy transition in the April 2024 edition of New Energy World. However, that article focuses mainly on the important issues of mechanical and material integrity and other safety concerns of the pipelines themselves, but does not mention the serious issues with the gas compression equipment outlined in this article.

Taking these issues together, a more holistic systems engineering approach to the idea of repurposing existing pipelines, together with a more realistic assessment of their real-world commercial and genuine sustainability impacts, is likely to generate considerably different conclusions.

An Energy Institute webinar on hydrogen compression, based on this new research, will be presented by the author on 5 November 2024 at 1pm BST. Tickets are free.

- Further reading: ‘On the horizon: Norwegian CCUS vision soon to be made real’. Despite cost overruns, Norway’s Northern Lights carbon capture, use and storage (CCUS) project is heading towards start-up in 2025, with a first-phase capacity of 1.5mn t/y, rising to 5mn t/y in the second phase. That schedule puts the scheme in the running to be among Europe’s first large-scale CCUS projects to start up.

- Find more about a new hydrogen production pilot plant that has officially opened in Kawasaki, Japan. The trial operation of the facility’s four 0.8 MW modules marks another step towards the commercialisation of large-scale green hydrogen production, according to the plant’s technology developer Asahi Kasei.