UPDATED 1 Sept: The EI library in London is temporarily closed to the public, as a precautionary measure in light of the ongoing COVID-19 situation. The Knowledge Service will still be answering email queries via email , or via live chats during working hours (09:15-17:00 GMT). Our e-library is always open for members here: eLibrary , for full-text access to over 200 e-books and millions of articles. Thank you for your patience.

New Energy World™

New Energy World™ embraces the whole energy industry as it connects and converges to address the decarbonisation challenge. It covers progress being made across the industry, from the dynamics under way to reduce emissions in oil and gas, through improvements to the efficiency of energy conversion and use, to cutting-edge initiatives in renewable and low-carbon technologies.

Designing the world’s first overground CO2 pipeline for CCUS hub in Teesside

10/7/2024

8 min read

Feature

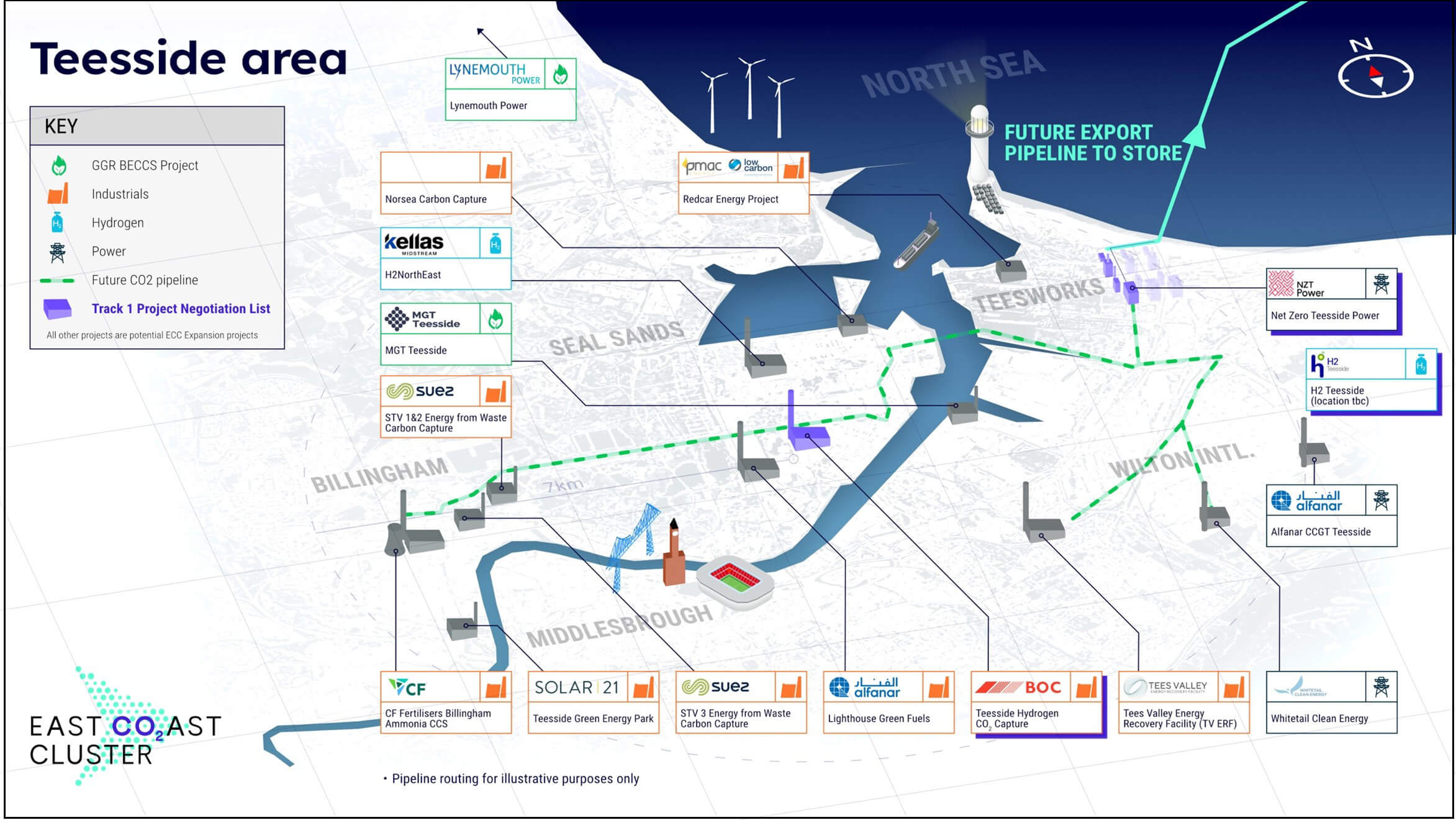

Two industrial projects in Teesside will see approximately 4mn t/y of CO2 collected from local emitters and safely transported for storage offshore via a new overground pipeline designed by Costain, reports Project Manager Niku Nobakhti.

The UK has clear commitments to achieve net zero and energy transition. Accomplishing these goals is only possible with a systematic approach. This has led to plans for several industrial clusters across the UK aimed at reducing carbon emissions and switching to low-carbon energy sources.

One of these clusters is the East Coast Cluster (ECC) which spans industries across the Teesside and Humber areas. This is one of the UK’s most densely industrial sites, emitting more carbon than any other cluster. It also has a rich heritage of adopting pioneering industries and technologies, which makes it ideal for implementation of one of the first UK carbon capture, utilisation and storage (CCUS) projects.

Net Zero Teesside Power (NZT Power), a joint venture between BP and Equinor, will be the world’s first commercial scale gas-fired power station equipped with carbon capture. The power station will integrate with the Northern Endurance Partnership (NEP), a separate joint venture between BP, Equinor and TotalEnergies, which will be the CO2 transportation and storage provider for the ECC.

These projects have two key elements. The first is 860 MW generation and distribution of low-carbon electricity for up to 1.3 million homes; along with a CCUS element, which will collect about 4mn t/y of CO2 from emitters in the local Teesside area and transport it for storage offshore. NZT Power and the NEP aim to take final investment decisions in September 2024 and are aiming for first commercial operations from 2027.

In early 2024, Costain completed the front-end engineering design (FEED) for NZT Power/NEP. The completed FEED design includes natural gas supply pipework and a high voltage 275 kV power network. For NEP, design work focused on the onshore CO2 gathering network. When finished, the 12 km of 22-inch diameter pipeline will transport around 4mn t/y of CO2 to be securely stored under the North Sea.

The system will connect key carbon emitters north of the Tees to the NZT Power plant for compression and subsequent transportation to offshore storage for captured CO2 emissions.

A diagram of the facilities linked by the new CO2 pipeline across Teesside

Source: Costain

Challenges

One of the main challenges for the transportation network related to the information and asset management required to enable the FEED work. The viability of the transportation network depends on the utilisation of the existing infrastructure and assets, constructed over many decades, under different ownerships, and designed to evolving design codes and industrial practices. Whilst adaptation of existing assets is not uncommon in brownfield projects, the FEED for the proposed network spanned over 20 different asset owners and working authorities, with varying levels of recordkeeping, design documentation and asset information.

Key to the success of the FEED was Costain creating a new geographic information system (GIS) to act as a single source of truth to capture asset information and data from a variety of sources and stakeholders. To achieve this, Costain partnered with PX Group to access and gather as much information as possible from asset owners throughout the route.

The use of GIS as a platform enabled data-driven design, that evolved through the FEED with new generated data as the design developed. The project saw the GIS platform loaded with both statutory and private utilities information, as well as environmental constraints, such as flood zones and noise receptor areas (as per the development consent order environmental statement), and ground investigation data from boreholes, trial pits and electromagnetic scans.

The digital-led design approach integrated ‘constructability’ into the early design development. This made it possible to divide the project into construction work areas and packages. This was key to identifying numerous constraints, including single-way traffic, the pinch points, height restrictions, controlled access gates and identifying construction access/work area requirements such as the easement zone around crane mats. For a project which is not restricted to a process plant physical perimeter fence, identification of these constraints early in the design phase is enormously beneficial.

Using a digital platform to superimpose data against developing design allows for a more dynamic and continual process of design reviews. As an example of its success, it was possible to overlay electromagnetic scans against historical drawings from the 1960s to inform geophysical reports and highlight potential areas of land contamination, which in turn informed pipeline routing.

The digital footprint that has been generated for the area is pioneering. It is the most comprehensive data set for the Teesside industrial area, which will remain a longstanding legacy for local industry and asset owners beyond completion of the project.

First of a kind

As well as the digital aspects of the project being pioneering, the pipeline itself is a world first. Once built, the CO2 gathering network is thought to be the first wholly vapour-phase above-ground network.

Above-ground CO2 pipelines pose unusual challenges as varying flow rates can be impacted by ambient conditions, due to the phase behaviour of CO2. It is possible that, under certain pressure and temperature conditions, CO2 in the pipeline can liquefy. Initially, the basis of the FEED was that there would be no liquids in the CO2 pipelines. The principle of the network is that emitters will be responsible for providing gas within specification to the network.

However, the FEED hazard and operability study (HAZOP) concluded that there were plausible scenarios for liquid formation and a possible full-bore leak if the CO2 pipeline was blocked. Such scenarios are modelled to be rare as they require abnormal (for example, no outlet flow) conditions to persist for long periods without operator intervention. However, there remains the potential for liquid formed in these circumstances to be released and flow along the line as slugs, where the liquid could coalesce, potentially damaging the line at any sharp bends. Given the proximity of some parts of the route to densely populated public areas and CO2 being a colourless asphyxiant, this risk needed to be designed-out as part of the FEED.

To understand the issue, the operation of the pipeline was simulated using Schlumberger’s OLGA (Oil and Gas Simulator) 2021 software, which was originally developed for oil and gas modelling but is equally effective for CO2. The software makes it possible to dynamically study the implications of changes in operating temperatures, pressures and flows.

Extensive flow assurance simulations and data modelling gave a better understanding of the dynamics of CO2 and its behaviours and, following quantitative risk assessments (QRA) and fault tree analysis (FTA), the design for a safe, resilient and efficient network was successfully completed. Findings showed that while liquid formation is possible, the formation of slugs is not a feasible scenario. Any liquid dropouts that form will flash back into vapour phase as the CO2 moves through the pipeline. Therefore, liquid formation in the pipeline could be accommodated within the existing design. Notwithstanding this, the additional forces exerted on existing infrastructure had to be assessed to ensure any liquid flows within the pipeline did not increase any stress loads and cause structural integrity concerns.

Along the route there are a total of 20 pipe bridges, and each had to be assessed for structural integrity and capacity. Historic design information for these pipe bridges was difficult to come by. As a result, assessments of the structures relied on a reverse-engineering approach that has been developed through years of experience in complex brownfield environments.

The CCUS building blocks are starting to come together – literally in the case of the East Coast Cluster – and will be key to the UK progressing along the path to net zero. In the future, we could see the industrial scale production and distribution of ‘clean’ hydrogen. Hydrogen production will go a long way towards supporting further decarbonisation efforts in industrial clusters by distributing low-carbon ‘blue’ hydrogen for use by industry as a replacement fuel stock, displacing natural gas and feeding into the national gas network.

Costain’s work on the FEED for the ECC’s CCUS system will leave a lasting digital legacy for the region. At the same time, we have obtained a new understanding of the characteristics of CO2 in this long, above-ground distribution network. This will be a transformational launch pad to enable future distribution networks to support the cluster and rejuvenate Teesside’s industrial heartland.

- Further reading: ‘CCUS: a silver bullet for a clean energy future?’ Carbon capture, utilisation and storage (CCUS) is seen as a promising bridge between fossil fuel dependence and a clean energy future, particularly in hard-to-abate industrial sectors. However, there are economic, technological, political and social issues to address.

- Repurposing existing infrastructure such as pipelines to transport alternative fuels such as CO2 or hydrogen can help accelerate the energy transition while reducing cost and waste. However, it is not without its challenges and must not compromise safety. New Energy Institute (EI) technical guidance aims to assist industry in this regard.